|

a |

|

- |

|

- |

|

- |

| careers |

|

|||||||||||||||||||||||||||||||||||

|

municipal | industrial | marine & dredging | agriculture | sanitation | mining | electrical | irrigation | communications | residential | landfill | recreation | road & highway construction | geothermal heating | ventilation | hydronic | fireworks | fish farms | floating docks | culvert | pontoons | tile | material handling |

||

Whether you manage a public landfill, a waste management system or just a privately owned garbage dump, the protection of the environment is going to be your paramount concern and a heavy responsibility. Designed to hold our garbage and to prevent it from contaminating our soil and our drinking water, the modern landfill has become a highly technical and complex structure. Contrary to what many might think, a landfill is not just a pile of garbage. To comply with federal mandates, a modern landfill has become complex system of rows and layers of garbage compacted into a series of cells or lifts, all of which are enclosed by a bottom liner made from a durable synthetic plastic, and embedded with a sophisticated system of plastic pipe.

Advantages of HDPE Landfill Gas Pipe

Our polyethylene pipe is used for wastewater distribution

where flexibility, corrosion resistance and durability are important

considerations. Landfill conditions present unique challenges for

any piping system. In a landfill, a piping system will have to withstand

external loads, be highly resistance to corrosive chemicals and

harsh environmental conditions. The flexibility and light weight

features of polyethylene pipe make it easy to assemble and install

especially where conditions are far from perfect. One of the biggest

advantages of using our pipe is its promise of leak free operation.

Because our landfill gas pipe can be joined by heat fusion, landfill

gas can be transferred to the processing plant without any fear

of leakage and harm to the surrounding environment.

As with many sanitary landfill projects, corrugated high density polyethylene pipe is used for leachate collection. Some of the pipe has to be buried beneath the landfill to divert the flow of water and resist any attack from chemicals that might leak out of the landfill. The inert properties of corrugated HDPE pipe allow it to handle strong leachate solutions ranging in pH from 1.5 to 14. The leak free pipe ensures that the landfill doesn't violate any regulations by contaminating the groundwater.

Plastic

Pipe for Leachate Collection

Plastic

Pipe for Leachate Collection

The most important thing you can do to prevent your garbage

from polluting the environment is to keep it as dry as possible.

When water is allowed to seep through your garbage, it collects

all the contaminants in the garbage creating something called leachate

or highly acidic water. To reduce leachate, a lot of landfills will

put your garbage through filters to remove any excess liquid and

will install perforated plastic storm drainage pipe and storm

liners to collect rainwater. These pipes collect the water and move

it to the drainage ditches surrounding the landfill site which drain

into a leachate collection pond From there the leachate is released

to a wastewater treatment plant where it is treated and recycled

back into the environment.

Plastic

Pipe for Methane Extraction

Plastic

Pipe for Methane Extraction

Another major problem with landfills, or any collection of compressed

garbage, is the production of methane gas. When your garbage is

compressed there is very little room for any oxygen. When bacteria

breakdowns your garbage, it creates a landfill gas, which contains

mostly methane and carbon dioxide with small amounts of nitrogen

and oxygen. To prevent the gas from exploding or bursting into flames,

a system or series of plastic pipes are embedded within the landfill

to extract the gas. In some cases, this gas is vented, burned off

or the methane is extracted and used as usable energy source.

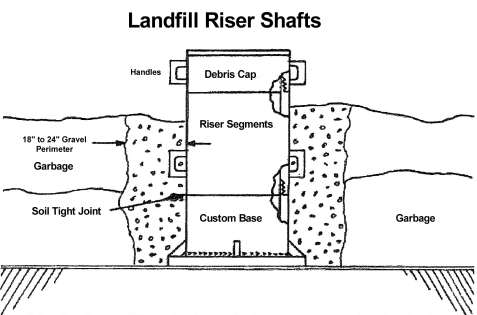

Landfill Riser Shafts

Once a leachate collection system is installed the landfill

will need risers over some of these pipes for periodic maintenance.

These riser shafts must have pipe continuously added to the riser

as the lifts of garbage and soil cover increase in height. Flanged

pipe spools are "grabbed" by the settlement of the garbage inducing

vertical axial buckling of the riser pipe column. Riser shafts must

be smooth on the OD to avoid vertical crushing! Vertical butt-fusion

of the large diameter pipes (with its smooth OD) is virtually impossible.

Hence, mechanical joining of the HDPE riser pipe is the answer!

The landfill riser system is composed of three segments: the Base, the Riser-Segment and the Cap. All these pipe components are fabricated from ruggedized HDPE pipe with at least 46 psi pipe stiffness. Each segment hand-screws into the other using two men laborers. As the garbage level rises and the riser needs to be vertically extended, the debris cap is unscrewed and removed by hand. The new Riser-Segment is hand threaded into place and the debris cap is reinstalled by hand threading it back into position. The short-length and lightweight HDPE pipe combine to make this a very practical system!

Call for a quote on the custom base needed for your landfill; add to it all the risers segments needed, and one debris-cap; and the landfill riser shaft is complete. The end user will want its engineer to do a structural analysis to verify adequacy of pipe for burial depth.

|

Nominal |

Custom Base |

Riser Segments |

Debris Cap |

|

|

Size |

(1.5" PL + 10ft) |

5 ft long |

10 ft long |

(with handles) |

|

24" ID |

|

|

|

|

|

36" ID |

|

|

|

|

|

42" ID |

|

|

|

|

Contact

us today by email or our toll free number:

sales@oxfordplasticsinc.com

1.800.263.0502

|

Copyright ® 2003 - 2008 | Oxford Plastics Inc. | All Rights Reserved |

|||

|

Oxford Plastics Inc. ~ PO Box 119, Oxford Road 6, Embro, Ontario, CANADA, N0J 1J0 |

|||

|

Office: 519.423.6232 ~ Fax: 519.423.6057 ~ Toll Free: 1.800.263.0502 |

Landfill

Gas Pipe

Landfill

Gas Pipe