|

a |

|

- |

|

- |

|

- |

| careers |

|

||||||||||

|

municipal | industrial | marine & dredging | agriculture | sanitation | mining | electrical | irrigation | communications | residential | landfill | recreation | road & highway construction | geothermal heating | ventilation | hydronic | fireworks | fish farms | floating docks | culvert | pontoons | tile | material handling |

||

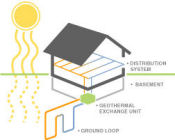

What is a Geothermal Heating System?

Geothermal systems use the earth as a heat source and heat sink.

They provide heat or cooling by moving heat, rather than by creating

heat like a furnace. Every system consists of three major subsystems

or parts: a geothermal heat pump to move heat between the building

and the fluid in the earth loop, an earth loop piping system for

transferring heat between its fluid and the earth, and a distribution

subsystem for delivering heating or cooling to the building.

No matter where you live, the underground temperature stays relatively constant all year within a degree or 2, even though outdoor temperatures vary widely. Geothermal systems harness this relatively constant, renewable energy source and use it for heating, air conditioning and hot water. - rewrite

Geothermal Pipe For Geothermal Earth Loops

Geothermal earth loops are made from high density polyethylene pipe.

A series of pipes, commonly called a "loop," carry a fluid used

to connect the geothermal system's heat pump to the earth. These

loops are either 3/4" or 1 1/4" diameter and the headers are either

1 1/4" or 2" diameter. We use a PE 3408 resin with high abrasion

resistance specifications that meets ASTM Standard Specification

D3350 with a cell classification of 345564 or 345434. This is the

specification mandated by US and Canadian Building Codes. Our geothermal

pipe has the same characteristics as the piping used for natural

gas lines and are joined by heat fusion. The heat exchanger in a

typical GHP system is made up of a closed or open loop pipe system.

The closed loop system is the most popular, in which high density

polyethylene pipe is buried horizontally at 4-6 feet deep or vertically

at 100 to 400 feet deep.

How

does it work?

How

does it work?

While the typical forced air heating system uses the outdoor air

as a source of heating, the geothermal system uses the underground

(earth or water) as a source of heating and cooling. Using an electrically-powered

water source heat pump, a geothermal heating system is basically

a system of pipes that act like a heat exchanger. Heat is collected

from the water collected below the earth's surface and transferred

to the air surrounding the pipe in a room or building. The heat

exchanger is either a closed or open loop pipe system. These pipes

are filled with an environmentally friendly antifreeze/water solution

that acts as a heat exchanger. In the winter, the fluid in the pipes

extracts heat from the earth and carries it into the building. In

the summer, the system reverses and takes heat from the building

and deposits it to the cooler ground.

Advantages of geothermal energy

The biggest advantage of a geothermal system is its ability to provide

a consistent and steady source of heat. While conventional heating

systems have to depend on outdoor temperatures that often vary,

underground temperatures remain relatively constant all year round,

producing the desired heating and cooling temperature year round.

The earth is a storage device for the sun's energy. Geothermal systems simply tap into this stored energy and transfer it to your home. Unlike fossil fuel heating systems geothermal systems transfer heat - they don't create it. - rewrite

Almost everywhere, the upper 10 feet of Earth's

surface maintains a nearly constant temperature between 10 and 16

degrees C. A geothermal heat pump system consists of pipes buried

in the shallow ground near the building, a heat exchanger, and ductwork

into the building. In winter, heat from the relatively warmer ground

goes through the heat exchanger into the house. In summer, hot air

from the house can be pulled through an equipped heat exchanger

into the relatively cooler ground. Heat removed during the summer

can also be used as no-cost energy to heat water with equipped units.

The use of low-grade geothermal energy for heating and cooling by

means of heat pumps has increased steadily in recent years. Today,

there are an estimated 30,000 units of 12 kW installed. - rewrite

- Lower energy costs and environment impact - a geothermal system uses 25-50% less electricity than conventional forced air heating or cooling systems. This means the less energy needed from burning fossil fuels that are harmful to the environment.

- Free or Cheap Hot Water - unlike any other heating and cooling system, a geothermal heat pump can provide free hot water using a device called a "desuperheater".

- Year-Round Comfort - maintains an even temperature and humidity level throughout your home with very little noise.

- Design Flexibility - geothermal heat pump systems allow for design flexibility and can be installed in both new and retrofit situations.

- Improved Aesthetics - geothermal systems are easy to conceal, don't require cooling towers, eliminate conventional rooftop equipment, less potential for leaks and ongoing maintenance, better roof warranties, allowing architects and building owners to plan for more aesthetically pleasing architectural designs and roof lines.

- Low Maintenance - since workhorse part of the system - the piping - is underground or underwater, there is little maintenance required.

- Zone Heating and Cooling - different areas of the building can be heated or cooled to different temperatures simultaneously, i.e., the heat from computer rooms can be moved to the perimeter walls for winter heating in commercial buildings.

- Durability - with virtually no moving parts, and parts that are sheltered inside a building, a geothermal heating system is durable and highly reliable. Our piping has a life span expectancy of up to 50 years or more.

Applications of geothermal pipe

Geothermal heating systems are a viable alternative anywhere there

is a need for heat or cooling. Using the ground or pond as a heat

sink in the summer and a heat source in the winter, heat is transferred

from the ground in the winter and extracted from the building in

the summer. Because of their design flexibility, they can be installed

in both new and retrofit situations. Because the hardware requires

less space than that needed by conventional HVAC systems, the equipment

rooms can be greatly scaled down in size, freeing space for productive

use. And since they usually use the existing ductwork in the building

there is no need for any extensive renovations. This makes geothermal

heating perfect for historical buildings, greenhouses, resorts and

any high-energy user with long operating hours.

NOTE: We are currently in the middle of installing another line for a geothermal heating system and need to sell out the product it will produce. We can ship this product all over North America. Please contact us if you are interested.

Contact

us today by email or our toll free number:

sales@oxfordplasticsinc.com

1.800.263.0502

To

learn more about the geothermal industry visit the links below:

Water

Furnace - WaterFurnace is the leading manufacturer of Geothermal

Heating and cooling equipment.

International

Ground Source Heat Pump Association (IGSHPA) - a non-profit

organization, established in 1987 to advance ground source heat

pump (GSHP) technology.

|

Copyright ® 2003 - 2008 | Oxford Plastics Inc. | All Rights Reserved |

|||

|

Oxford Plastics Inc. ~ PO Box 119, Oxford Road 6, Embro, Ontario, CANADA, N0J 1J0 |

|||

|

Office: 519.423.6232 ~ Fax: 519.423.6057 ~ Toll Free: 1.800.263.0502 |

Geothermal Pipe

Geothermal Pipe