|

a |

|

- |

|

- |

|

- |

| careers |

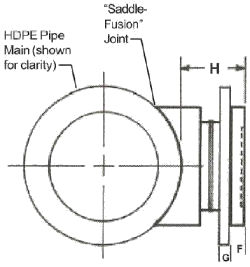

IPS & DIPS Tapping Sleeve / Saddle Assembly

|

|||||||||||||||||||||||||||||||||||||||||||

|

Outlet |

Main Size Range |

G (Back Up Ring) |

F (Flange Face) |

H (Height) |

DR | WPR (psi) |

|

4" |

6 - 12 |

0.94 |

1.00 |

8.50 |

11 |

160 |

|

6" |

8 - 12 |

1.00 |

1.25 |

8.50 |

11 |

160 |

|

8" |

10 - 12 |

1.12 |

1.50 |

9.00 |

11 |

160 |

|

10" |

12 |

1.19 |

2.00 |

10.50 |

11 |

160 |

|

12" |

14 - 34 |

1.50 |

2.25 |

10.50 |

11 |

160 |

See

Cutter Sizes for Taps for information

on cutter sizes for taps.

CAUTION:

Insure that the filed fusion equipment has adaptors to hold the

assembly with sufficient clearance opening and closure stroke to

complete fusion.

User

supplied longer bolts may be required to accept flange face and

metal back up ring.

Contact

us today by email or our toll

free number:

sales@oxfordplasticsinc.com

1.800.263.0502

|

Copyright ® 2003 - 2008 | Oxford Plastics Inc. | All Rights Reserved |

|||

|

Oxford Plastics Inc. ~ PO Box 119, Oxford Road 6, Embro, Ontario, CANADA, N0J 1J0 |

|||

|

Office: 519.423.6232 ~ Fax: 519.423.6057 ~ Toll Free: 1.800.263.0502 |

The

normal method of field tapping a mainline is to apply a tapping

saddle and tap through the tapping valve into the main, remove the

cutter and coupon and close the valve. It is advantageous to fabricate

a branch saddle fused to flange adaptor with a one-piece metal back

up ring captured between, this has been done for years. These "wet-tap"

assemblies are fabricated to minimize the vertical height from the

pipe crown to the flange face. This assembly complies with MSS SP-60,

the Standard Practice of the MSS (Manufacturers Standardization

Society of the Valve and Fittings Industry, Inc.) These assemblies

are engineered to accept tapping valves, whereas ordinary flanges

will not accept tapping valves. The assembly consists of custom-engineered

branch saddle fused to a customized flange adaptor with a centered

back up ring. Tapping Sleeve / Saddles are nominally fused to the

main pipe on the horizontal.

The

normal method of field tapping a mainline is to apply a tapping

saddle and tap through the tapping valve into the main, remove the

cutter and coupon and close the valve. It is advantageous to fabricate

a branch saddle fused to flange adaptor with a one-piece metal back

up ring captured between, this has been done for years. These "wet-tap"

assemblies are fabricated to minimize the vertical height from the

pipe crown to the flange face. This assembly complies with MSS SP-60,

the Standard Practice of the MSS (Manufacturers Standardization

Society of the Valve and Fittings Industry, Inc.) These assemblies

are engineered to accept tapping valves, whereas ordinary flanges

will not accept tapping valves. The assembly consists of custom-engineered

branch saddle fused to a customized flange adaptor with a centered

back up ring. Tapping Sleeve / Saddles are nominally fused to the

main pipe on the horizontal.