Branch Saddle Heater Plate Information

Most common branch saddles are produced by machining a branch of

a molded tee. Their reinforcement is meant for that size on size

tee! It was not engineered to meet all reducing outlet tee design

combinations. For example, using the area or volume replacement

method of ASME B31.3 for reinforcement, the bore-hole mass drilled

from a 24" DR11 pipe wall for a 2" outlet, is about 6.5

cubic inches. The muff area around the 2" tee-type branch saddle

is not nearly 6.5 cu. in. Thus the 2" tee-type branch saddle

on a 24" DR 11 pipe is not fully pressure rated. The muff reinforcement

of the 2" branch saddle has sufficient mass on it to fully

pressure-rate 3" x 2", 4" x 2" and 6" x

2" reducing tee. Above 6" mains, the 2" saddle reinforcement

does not fully replace the mass of the pipe wall removed for the

outlet hole. Each branch saddle reinforcement should be reviewed

for its capacity to replace the mass of the hole drilled thru the

specified pipe-main in order to maintain a full working pressure

rating.

The Massive Branch Saddles (MBS) of the DIPS sizes are engineered

to cover a wide range of reducing outlets thru 24" DIPS pipe

mains. The mass of the base reinforcement exceeds the mass of the

hole cut from the main to which it will be fused. Thus the full

pressure rating is preserved.

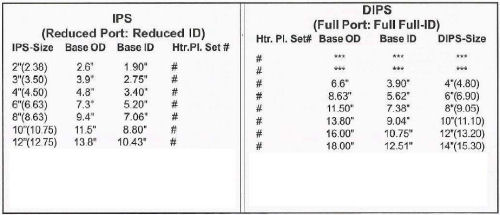

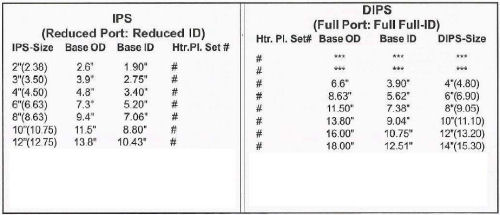

Most contractors wish to use the same header plates that they now

have. This is accomplished by jumping one base size or diameter

compared to the outlet diameter, starting with the 4" outlets.

For example, to fuse on a 4" DIPS outlet, investigate using

a 10" IPS or 8" DIPS heater plate set. Contact your fusion

equipment manufacturer to record below, the following Heater Plate

Sets that apply for your fusion machine:

"IPS" Massive Branch Saddles designed for full bore,

full pressure rating for all main & outlet combinations are

available.

Contact

us today by email or our toll

free number:

sales@oxfordplasticsinc.com

1.800.263.0502

|