Branch Saddle Design Information

Fully Pressure-Rated Branch-Saddle Fittings

A pipe having a branch outlet connection is weakened by the opening

that must be made in it. Unless the wall thickness of the pipe is

sufficiently in excess of that required to sustain the full pressure,

it is necessary to provide added reinforcement. The amount of added

reinforcement required to sustain the pressure is governed by the

area replacement method. Basically, the volume of the pipe-wall

coupon from the hole for the branch is replaced by added volume

and mass in critical zones around the branch outlet. This methodology

is detailed in ASME Code for Pressure Piping B31.3 "Process

Piping" section #304.3.2 and #304.3.3. Where the 800 psi hoop-stress

of the branch outlet and the 800 psi hoop-stress of the main pipe

meet at the joint intersection, extra material must be added to

reduce the intensified stress in the joint to the allowable 800

psi long term stress.

Branch Connection Nomenclature ASME

B31.3-1996 Edition

Tests conducted on non-reinforced branch connections proves that

the branch outlet in line tees and reducing tees are generally reduced

in strength by about 45% depending on the ratio of the pipe diameters.

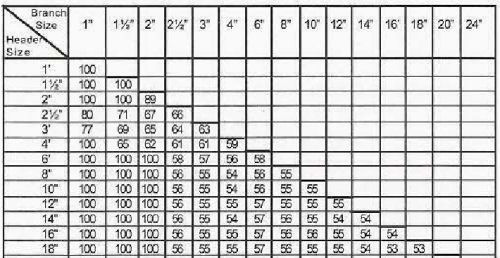

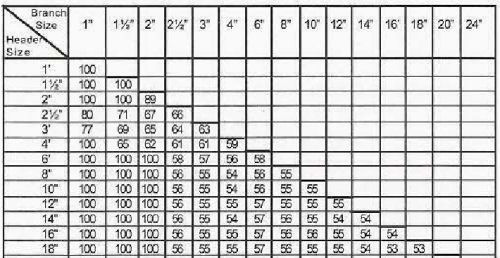

Pressure Reduction Ratios in Percent for Unreinforced

Intersections*

*Based on the Code for Pressure Piping, ASA B31.1

for standard weight pipe with 0.1 corrosion allowance: let of Fillet

weld =1/4" for branches 4" or smaller, and 3/8" for

larger branch sizes.

Contact

us today by email or our toll

free number:

sales@oxfordplasticsinc.com

1.800.263.0502

|